Loading chunks of glass into a mold to be melted down and 'spin cast' into one of the seven 8.4-meter mirrors for the GMT. This image, as well as other images and videos, are available for download here.

Sixth Mirror Cast for Giant Magellan Telescope

5 March 2021

The 8.4-meter mirror joins five of the world’s largest mirrors previously cast for the Giant Magellan Telescope, one of the world’s largest and most anticipated extremely large telescopes.

AUSTIN, Texas — The University of Texas at Austin and other partners of the Giant Magellan Telescope (GMT) announce the fabrication of the sixth of seven of the world’s largest monolithic mirrors. These mirrors will allow astronomers to see farther into the universe with more detail than any other optical telescope before. The sixth 8.4-meter (27.5 feet) mirror — about two stories high when standing on edge — is being fabricated at The University of Arizona’s Richard F. Caris Mirror Lab and will take nearly four years to complete.

“This mirror casting brings the faculty, students, and researchers of The University of Texas at Austin one step closer to having access to the unique scientific tool that is the Giant Magellan Telescope,” said Taft Armandroff, Director of the university’s McDonald Observatory and Vice Chair of the GMT Organization’s Board of Directors.

The process of casting the giant mirror involves melting nearly 20 tons (38,490 pounds) of specialized glass into the world’s only spinning furnace designed to cast giant mirrors for telescopes. At the peak of the melting process, the furnace spins at five revolutions per minute, heating the glass to 1,165 degrees Celsius (2,129 F) for approximately five hours until it liquefies into the mold. The peak temperature event is called “high fire,” and will occur tomorrow, March 6.

The mirror then enters a one month annealing process where the glass is cooled while the furnace spins at a slower rate in order to remove internal stresses and toughen the glass. It takes another 1.5 months to cool to room temperature. This “spin cast” process gives the mirror surface its special parabolic shape. Once cooled, the mirror will be polished for two years before reaching an optical surface precision of less than one thousandth of the width of a human hair.

“The most important part of a telescope is its light-collecting mirror,” said James Fanson, GMT Project Manager. “Once operational, the Giant Magellan Telescope will produce images ten times sharper than the Hubble Space Telescope. The discoveries these mirrors will make will transform our understanding of the universe.”

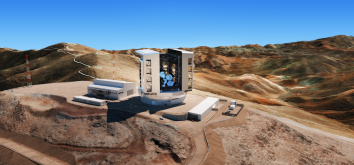

With the first two giant mirrors completed and in storage in Tucson, the sixth mirror joins three others in various stages of production at the mirror lab. In the late 2020s, the giant mirrors will be transported more than 8,100 kilometers (5,000 miles) to the GMT’s future home at Las Campanas Observatory in Chile. One of the best astronomical sites on the planet, it has clear skies, low light pollution, and stable airflow, producing exceptionally sharp images. The southern hemisphere location gives GMT access to the center of the Milky Way and its supermassive black hole — as well as many of the most interesting nearby galaxies.

Once the GMT becomes fully operational, its seven-mirror array will have a total light collecting area of 368 square meters (3,961 square feet) — enough to see the torch engraved on a dime from nearly 160 kilometers (100 miles) away. The mirrors help give the GMT the widest field of view of any of the forthcoming telescopes in the 30-meter class.

“This unprecedented combination of light gathering power, efficiency, and image resolution will enable us to make new discoveries across all fields of astronomy, particularly fields that require the highest spatial and spectral resolutions, like the search for other Earths,” said Rebecca Bernstein, GMT Chief Scientist. “We will have unique capabilities for studying planets at high resolution, which is the key to understanding if a planet has a rocky composition like our Earth, if it contains liquid water, and if its atmosphere contains the right combination of molecules to signal the presence of life.”

The GMT project is the work of a distinguished international consortium of leading universities and science institutions. For more information, visit https://www.gmto.org.

— END —